PRODUKTE

Product range

No matter whether you need a shell-and-tube or plate heat exchanger, an air cooler, or any other type of heat exchanger, our exceptionally wide product range enables us to choose the best product for every use.

The frame size of the different products varies from a few Centimeters up to the size of a High Cube 40' container, while the weights are in a range of a few kilograms up to about 20 tons.

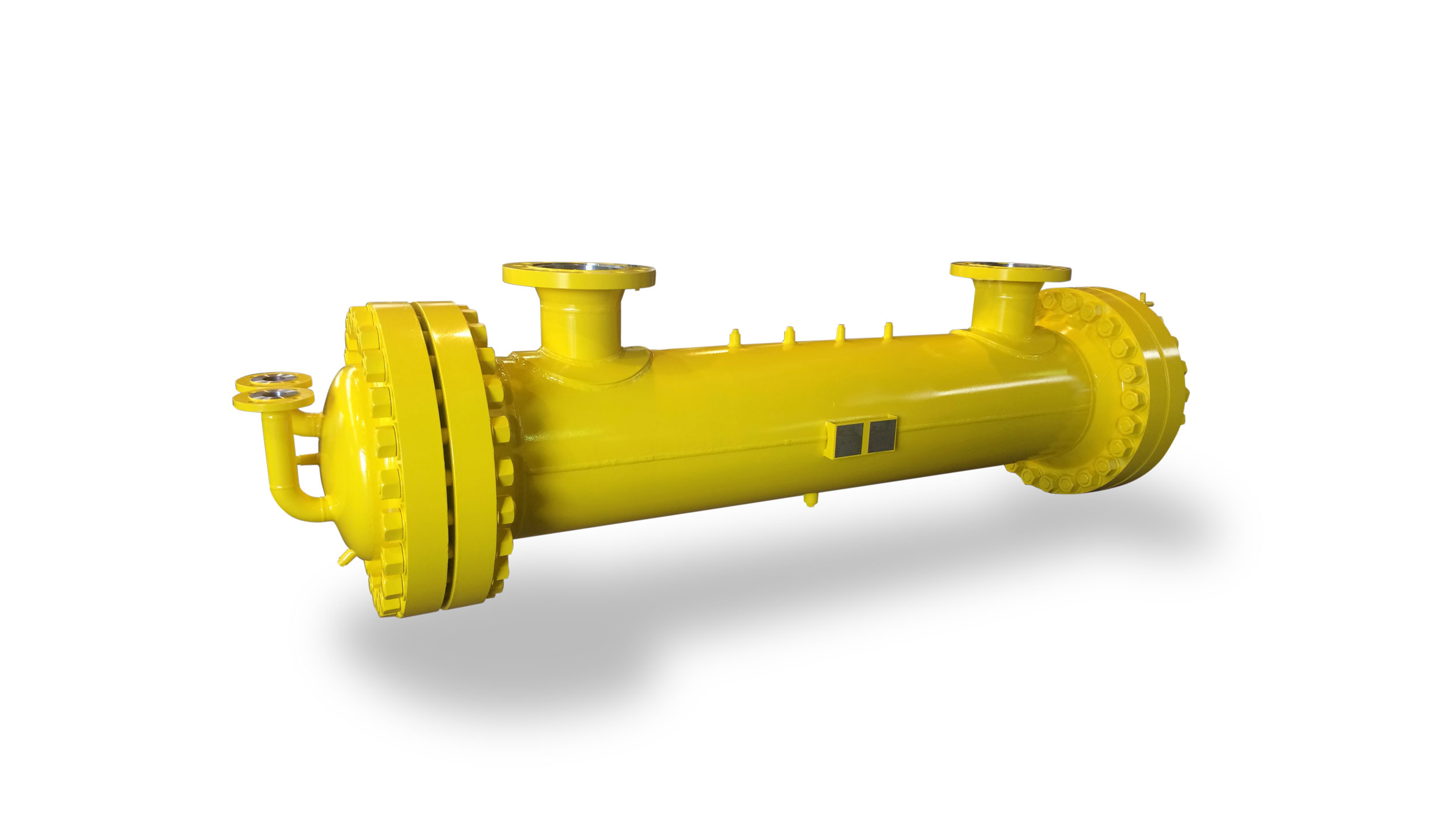

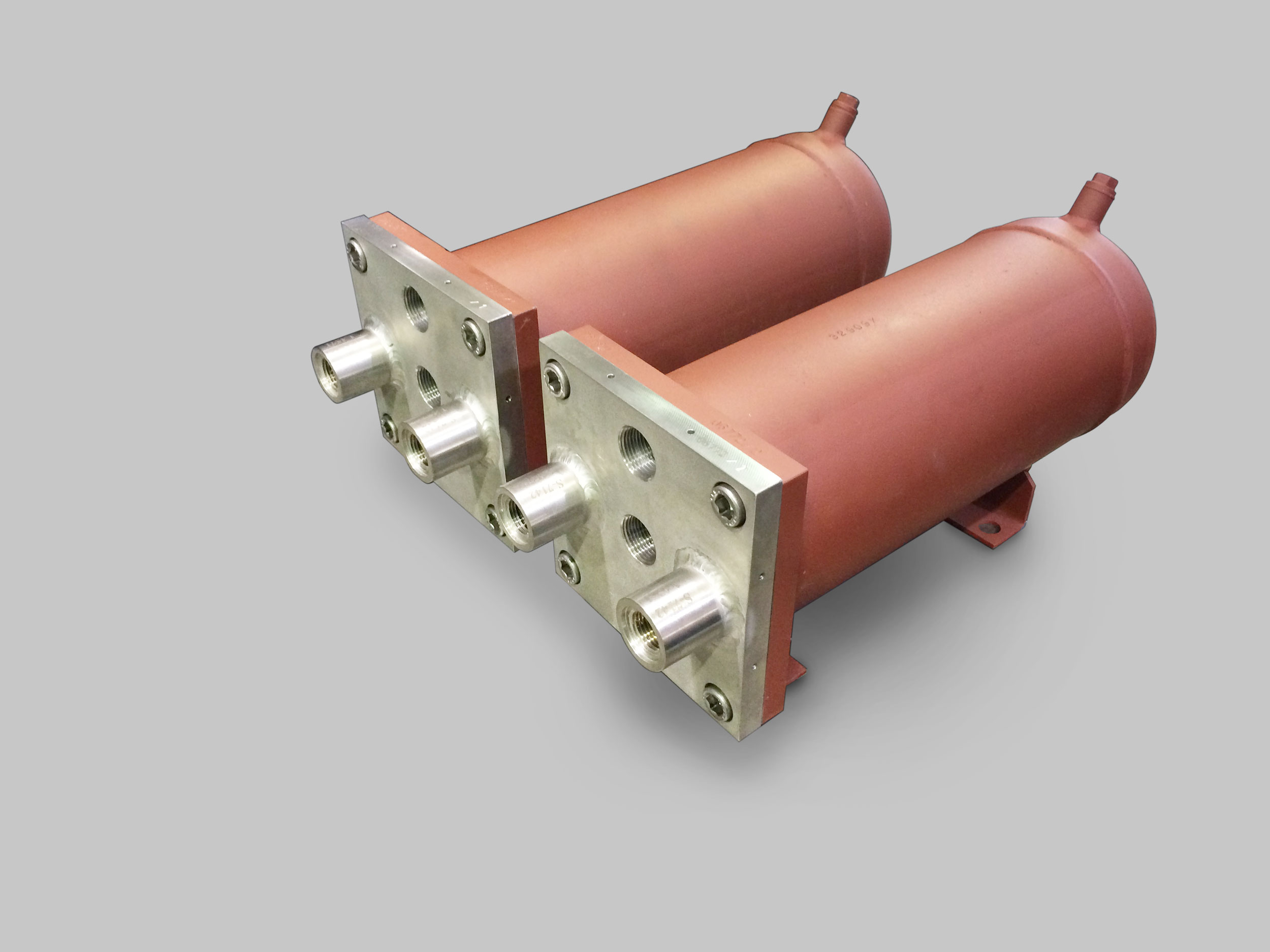

Shell-and-tube bundle heat exchanger

The classical shell-and-tube heat exchanger can be found in many industrial applications.

All kinds of specifications, certifications and special requirements can be applied on it.

It can also be realized as a double pipe safety heat exchanger.

For very compact and cost-optimized heat exchangers we have special solutions to enlarge the transfer surface on the inner- and outer side of the heat exchanger tubes. These solutions are particularly suitable for viscous media and gases.

Type RGL = Smooth pipe heat exchanger

The conventional tube bundle heat exchanger has similar transfer surfaces on the inner- and outer sides of the tubes. Therefore it is suitable for media with similar heat transfer properties.

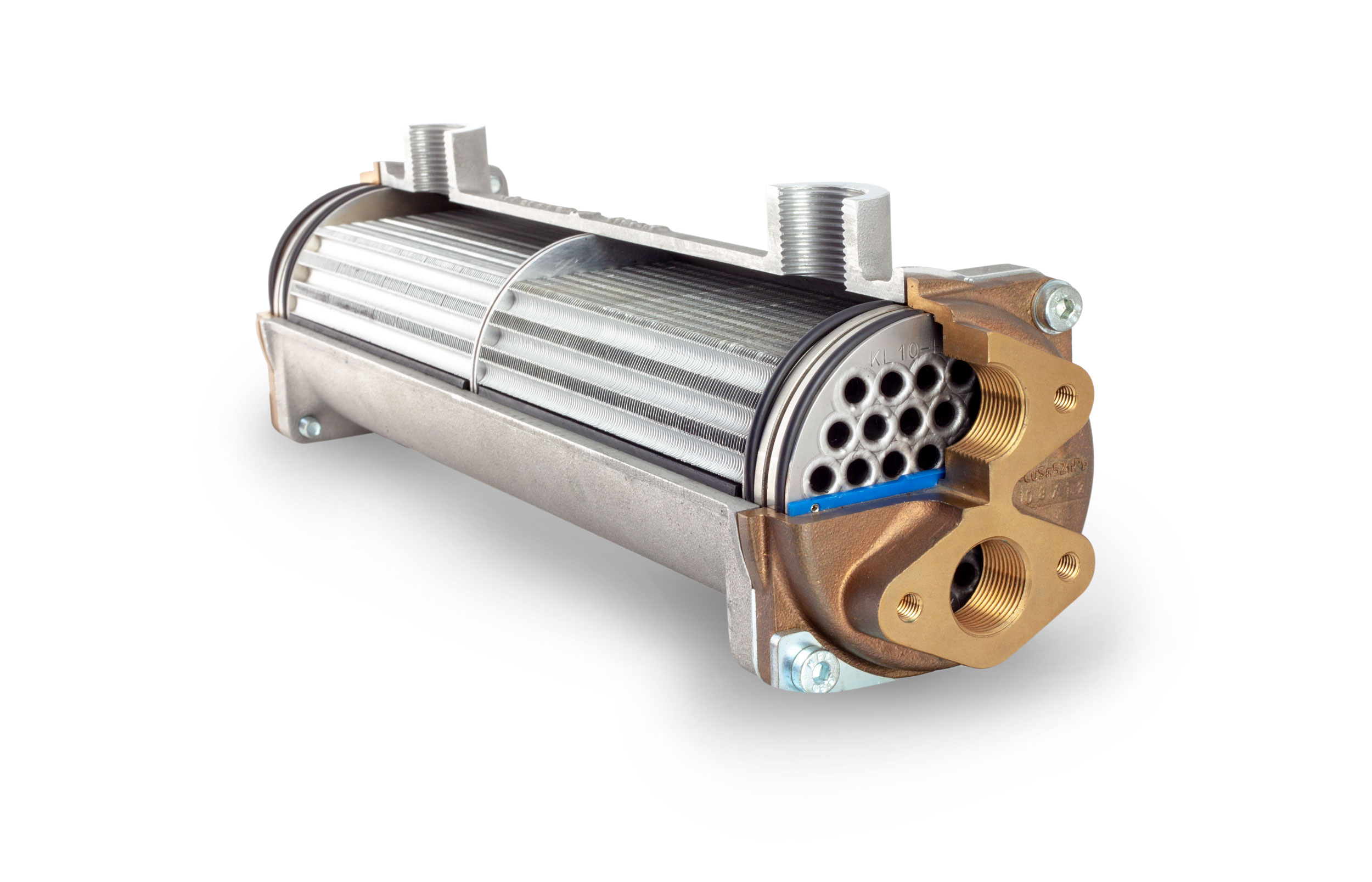

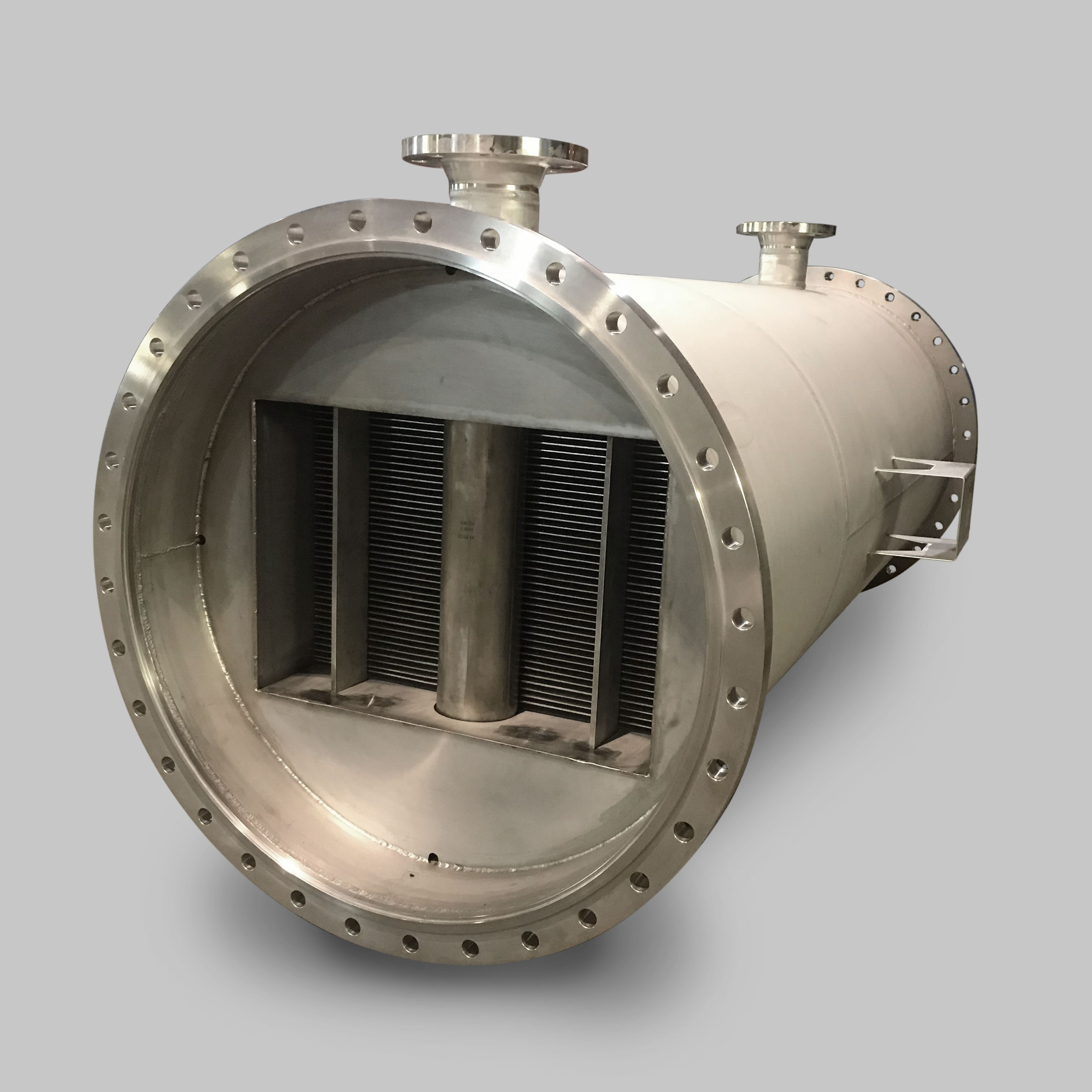

Type RLP = tube bundle fin-paket block heat exchanger

This type has continuous fins on the outer side of the tubes. This leads to a significant enlargement of the surface, which makes this type especially suitable for viscous media like oil or gas. The media will flow through the shellside and the cooling water through the tubes.

Type RIS = tube bundle inner star heat exchanger

This type contains star shaped fins inside the tubes, which leads to a significant enlargement of the surface. It is suitable for viscous media like oil or gas. Hereby the media will flow through the tubes and the cooling water through the shellside.

Available Materials:

- Steel

- Stainless Steel

- Copper

- Copper Aloys

- Brass

- Aluminium

- Duplex

- Superduplex

- Titanium

- and others

Available Certifications

- PED 2014/68/EU with CE-Labelling

- TR CU 032 with EAC-Labelling

- ASME VIII Div. 1 with U-Stamp

- DNV GL

- BV Mode II Scheme

- Lloyd´s Register

- China Manufacturing License (SELO)

- CRN (Canada)

- DOSH (Malaysia)

- KOSHA, KGS (Korea)

- and others

Calculation Codes and Design Specifications

- AD 2000

- EN 13445

- ASME VIII Div. 1

- Gost R 52630

- TEMA

- API 660, API 682, API 614

- Customized Design Specifications

- and others

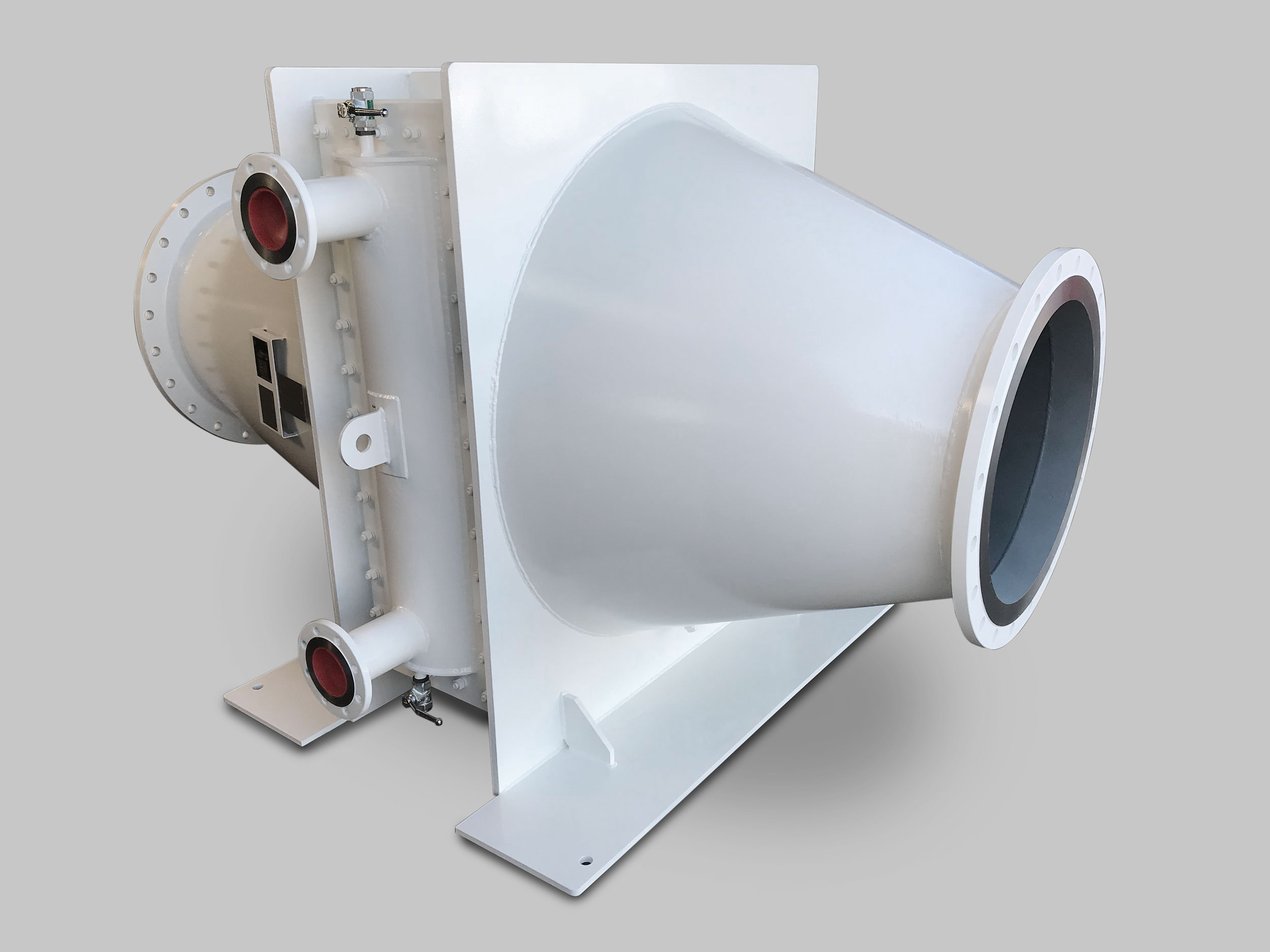

Air cooler and Gas Heater

Air cooler are used in numerous applications for cooling media with surrounding air. For this purpose square units of heat exchangers assembled from bare tubes, finned tubes or finned packages will be used. We offer this type normally with forced or induced draft fans. In addition there are constructions with louvers for air control available.

In combination with a pressure resistant shell, these types of heat exchangers can be used as air-heater or for process-gas cooling as well.

In addition our air cooler can be designed as double pipe safty heat exchanger.

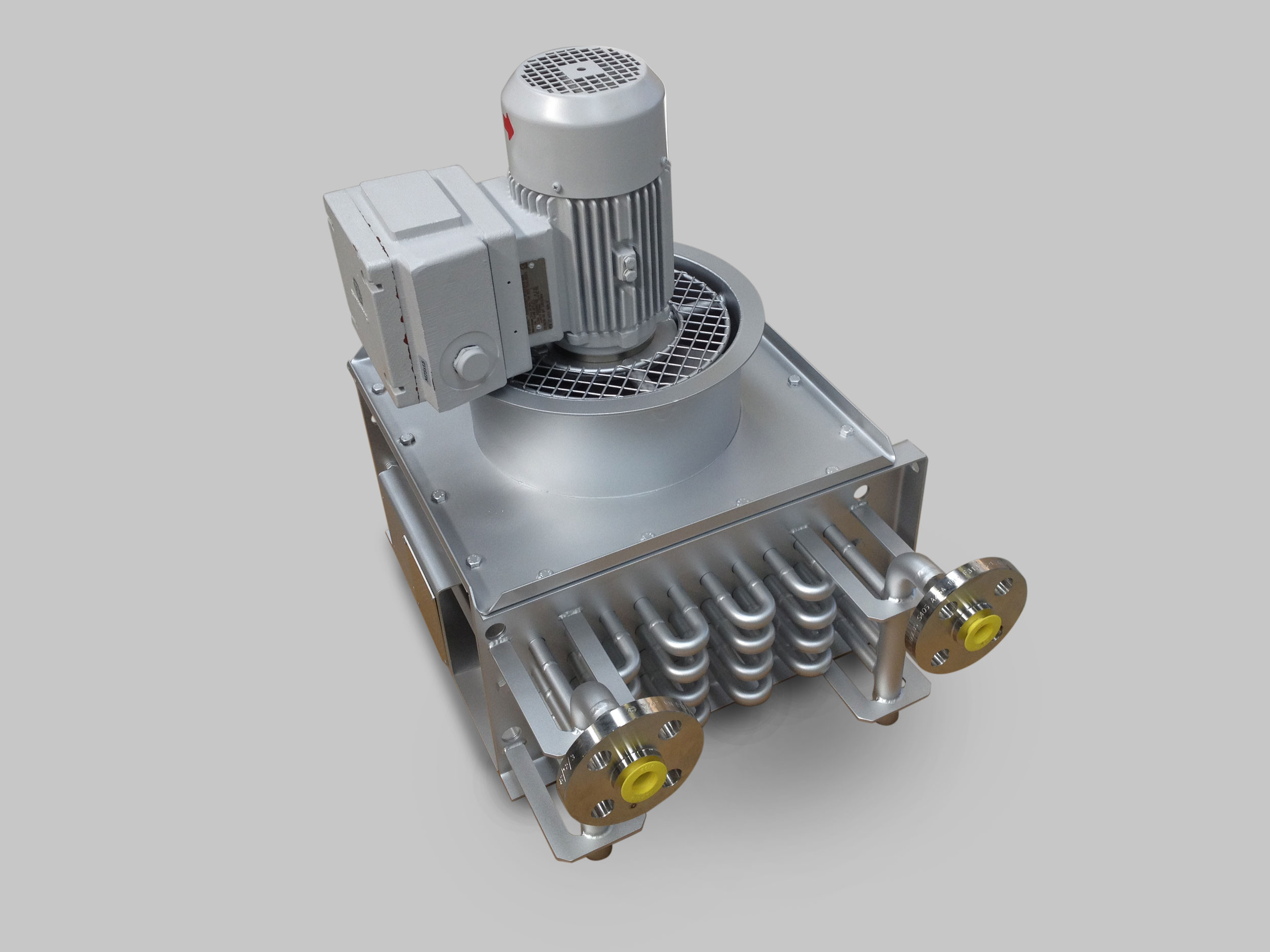

Type LKV = Air cooler with fan

This heat exchanger type will be delivered including fans and electrical drive.

Upon request designs as recirculation units with automatic louver control are available. Furthermore policies like API 660 with or without plug headers can be applied.

The tube-side can be designed for high pressure up to 800 bar.

Type REG = fin block heat exchanger

This type consists of a rectangular heat exchanger register, which is manufactured either from bare, finned or continuously finned pipe. On the outside it can be build in an air channel or driven by free convection.

The tube-side can be designed for high pressure up to 800 bar

Type REG with pressure-resistant case

This type contains a pressure-resistant case and can be used either with positive or negative pressure at the outside of the heat exchanger tubes.

It is suitable for heating or cooling process gases.

Available Materials:

- Steel

- Stainless Steel

- Copper

- Copper Aloys

- Brass

- Aluminium

- Duplex

- Superduplex

- Titanium

- and others

Available Certifications

- PED 2014/68/EU with CE-Labelling

- TR CU 032 with EAC-Labelling

- ASME VIII Div. 1 mit U-Stamp

- DNV GL

- BV Mode II Scheme

- Lloyd´s Register

- China Manufacturing License (SELO)

- CRN (Canada)

- DOSH (Malaysia)

- KOSHA, KGS (Korea)

- and others

Calculation Codes and Design Specifications

- AD 2000

- EN 13445

- ASME VIII Div. 1

- Gost R 52630

- API 661, API 614, API 682

- Customized Design Specifications

- and others

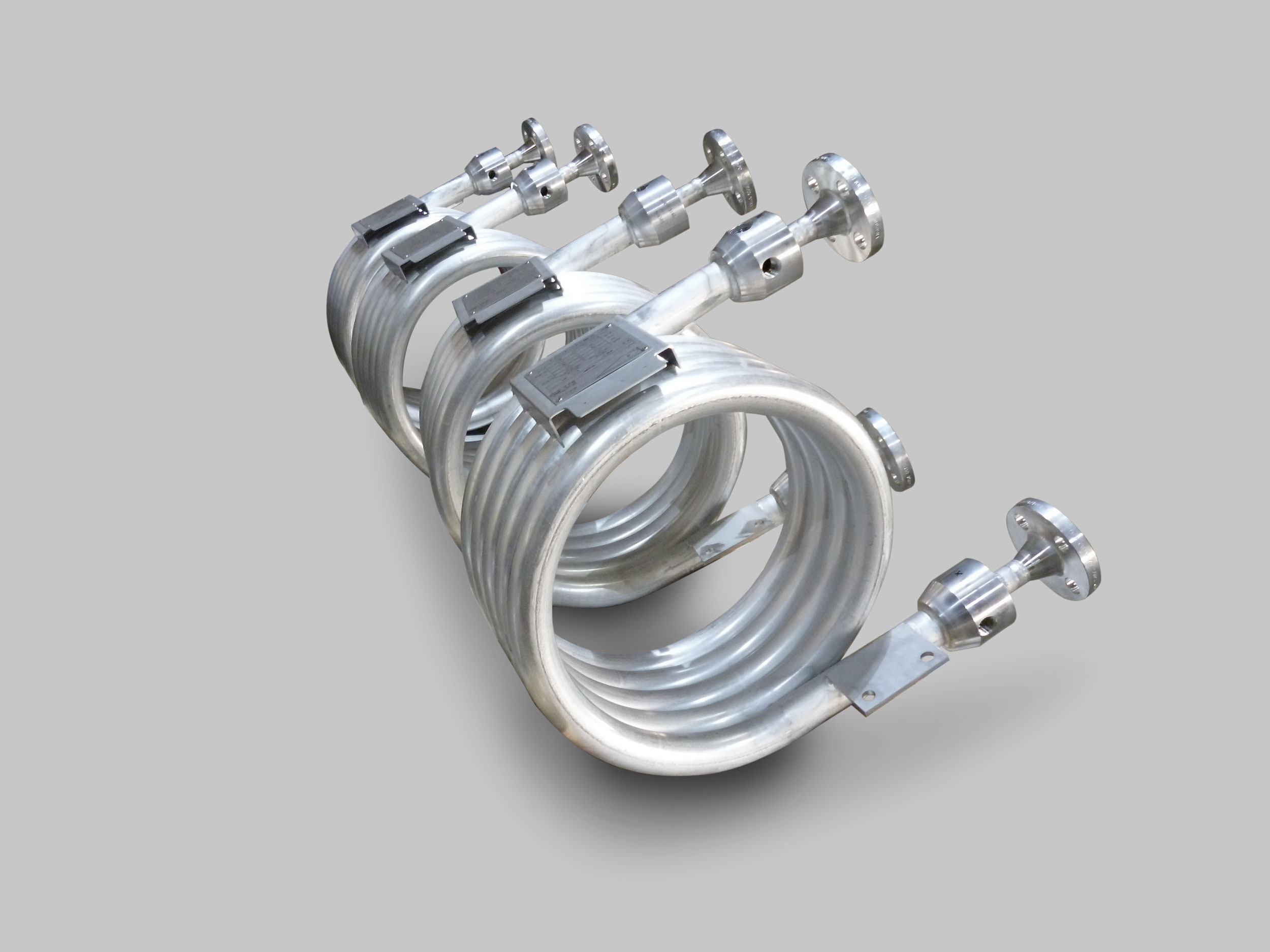

Coiled tube- and coaxial heat exchanger

Coiling long heat exchanger tubes results in a very efficient construction. This construction can be offered either as a tube coil in a pressure vessel (type WGL), or as coiled double pipe (type COX).

Both designs are suitable for media with similar properties of heat transfer because there is no surface enlargement possible on one side.

the flow inside a coiled double pipe coaxial heat exchanger (type COX) is equivalent to a perfect countercurrent heat exchanger and is especially suitable for processes with overlapping temperatures of both media. This happens in many heat recovery processes.

Verfügbare Materialien:

- Stahl

- Edelstahl (ganz nach Kundenwunsch)

- Kupfer

- Kupferlegierungen

- Messing

- Aluminium

- Duplex

- Superduplex

- Titan

- und weitere

Verfügbare Zertifizierungen

- PED 2014/68/EU mit CE-Kennzeichnung

- TR CU 032 mit EAC-Kennzeichnung

- ASME VIII Div. 1 mit U-Stamp

- DNV GL

- BV Mode II Scheme

- Lloyd´s Register

- China Manufacturing License (SELO)

- CRN (Canada)

- DOSH (Malaysia)

- KOSHA, KGS (Korea)

- und weitere

Berechnungscodes und Designvorschriften

- AD 2000

- EN 13445

- ASME VIII Div. 1

- Gost R 52630

- API 614, API 682

- Kundenspezifische Designvorschriften

- und weitere

Plate heat exchanger

A widespread design of heat exchangers which are economically worthwhile for media with similar heat transfer properties. Our plate heat exchangers are manufactured with high-quality materials and are available in sealed (type PLG), soldered (type PLB) and welded (type PLW) versions.

Available Materials:

- Stainless steel (1.4404/ 316L)

- Copper

- Titanium

- and others

Available Certifications

- PED 2014/68/EU with CE-Labelling

- ASME VIII Div. 1 without U-Stamp

- DNV GL

- and others

Calculation Codes and Design Specifications

- AD 2000

- EN 13445

- ASME VIII Div. 1

- and others

Laser-welded plate heat exchanger

In the simplest version this product contains of only 2 plates, which are laser-welded together and expanded afterwards. There is a wide range of applications possible, like the production of ice, drying of solids like tobacco, or bringing up temperature on walls and ovens. We even like to offer special devices like head condensers made of several laser-welded heat exchanger plates.

Available Materials

- Steel

- Stainless Steel

- Duplex

- Superduplex

- Titanium

- and others

Available Certifications

- PED 2014/68/EU with CE-Labelling

- TR CU 032 with EAC-Labelling

- ASME VIII Div. 1 without U-Stamp

- China Manufacturing License (SELO)

- and others

Calculation Codes and Design Specifications

- AD 2000

- EN 13445

- ASME VIII Div. 1

- Customized Design Specifications

- and others

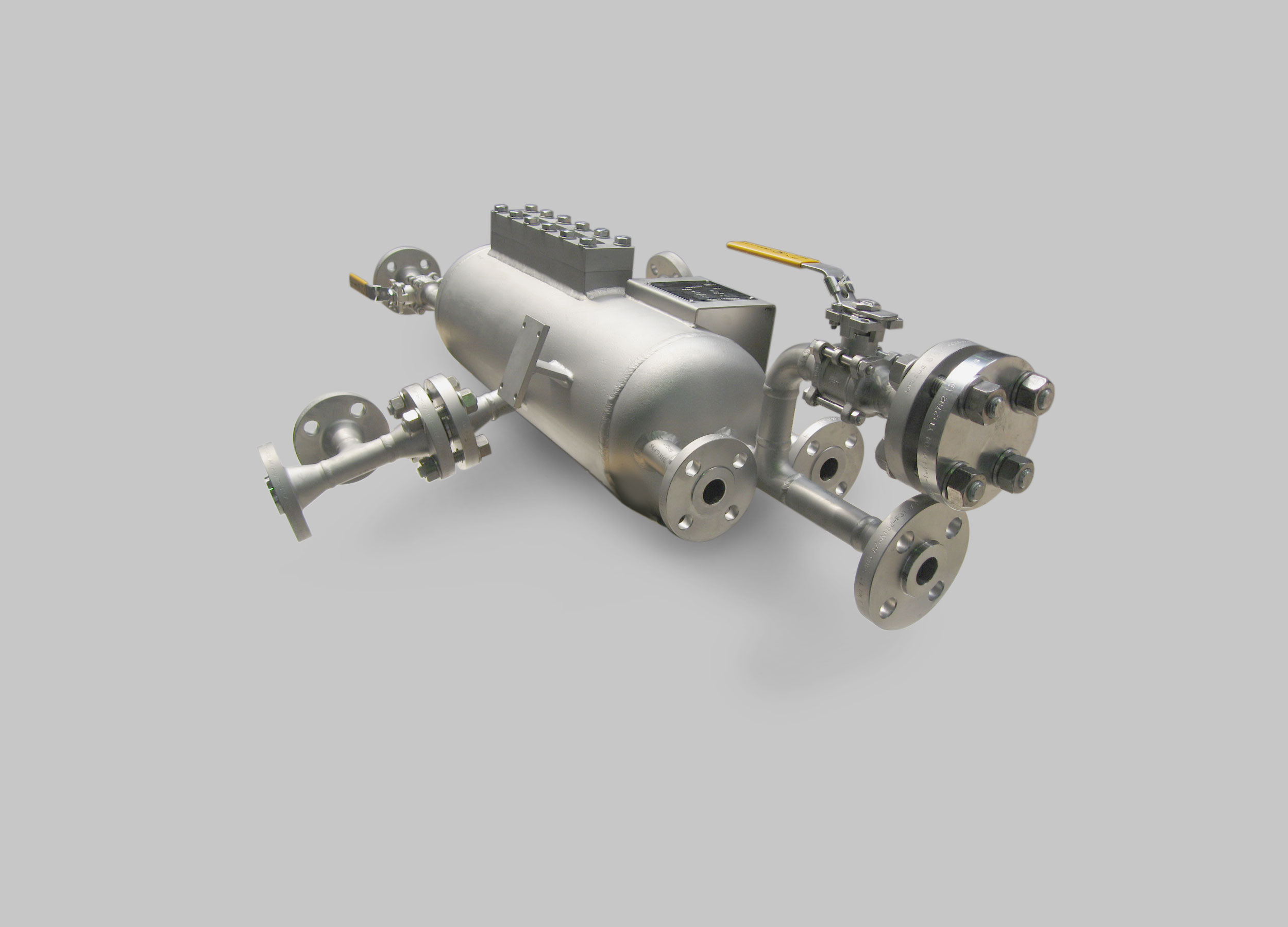

Special vessels and devices

Beside the previously listed products, we also offer various pressure vessels and devices like condensate separators, reactors and storage tanks. These can be offered with various materials and different certifications. We can also take customer wishes and design specifications into consideration.

Available Materials:

- Steel

- Stainless Steel

- Copper

- Copper Aloys

- Brass

- Aluminium

- Duplex

- Superduplex

- Titanium

- and others

Available Certifications

- PED 2014/68/EU ith CE-Labelling

- TR CU 032 with EAC-Labelling

- ASME VIII Div. 1 with U-Stamp

- DNV GL

- BV Mode II Scheme

- Lloyd´s Register

- China Manufacturing License (SELO)

- CRN (Canada)

- DOSH (Malaysia)

- KOSHA, KGS (Korea)

- and others

Calculation Codes and Design Specifications

- AD 2000

- EN 13445

- ASME VIII Div. 1

- Gost R 52630

- Customized Design Specifications

- and others

IWS-Monjé Heat Exchangers GmbH

Wittener Straße 56

44789 Bochum

Germany

Tel.: +49 234 33829640

info@iws-monje.com

Products

Applications

Privacy policy